Parts and Spares

We provide a full suite of replacement parts and spare components for the Watermiser Cooling Tower as well as other brands. We can react to urgent requests, or help you plan ahead to make sure that you have the right spares to hand should the need arise. Please contact us on [email protected] if you require spares for your cooling tower.

Some of the more common spares requests are for:

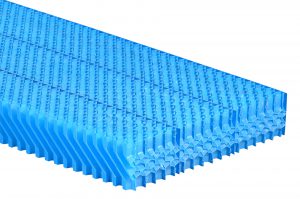

Heat Transfer Pack

This is a critical part of the cooling tower which allows the energy transfer between the air and water to take place.

We can advise on the most suitable pack for your application to ensure that you are achieving the optimal energy transfer for your process and with consideration to the water quality present in your application.

Drift Eliminators

Cooling towers rely on drift eliminators to reduce the loss of water and emissions. Located above the spray distribution system and the heat transfer pack, the drift eliminator is the final component before the air is emitted to the atmosphere.

The water droplets are captured by the drift eliminators, preventing them from being carried away by the exiting airflow, and are then redirected back into the cooling water circuit. Correct selection of drift eliminators reduces water loss and ultimately water cost of the cooling tower.

Regularly inspection of the eliminators is essential to ensure that they are correctly fitted and are operating effectively. Watermiser can provide such inspection services.

Find out more about our Inspection Service

Replacement Spray Water Distribution

The spray water distribution system ensures that the cooling water is properly presented to the heat transfer pack to ensure maximum heat transfer is achieved.

We now use stainless steel as our standard offering for the inlet water header with welded screwed sockets for the spray arms. This latest design provides a strong and serviceable feature providing the user with a component with a long term service life in keeping with the overall design of the Watermiser tower itself.

The new stainless steel header can also be provided for existing Watermiser cooling towers with a straight forward retrofit. As part of our latest spray water distribution system we also provide Cobra clip style fastenings to further support the water distribution spray arms.

Replacement Fan and Associated Components

The fan is the hardest working component in the cooling tower given the static nature of many other components. While every effort is made in the design of the cooling tower to minimize the fans exposure to water, it is located adjacent to a moist and chemically rich environment. The location of the fan on the Watermiser tower at low level is ideal as it can be easily inspected, repaired and replaced.

If you have any queries about fan/component availability (be that for a Watermiser tower or an alternative manufacturer) such as motors, impellers, terminal boxes etc. then do give us a call.

Attenuation Equipment

We can supply attenuation equipment either with the tower or as a retrofit item in the form of silencer and/or acoustic panelling.

GRP Ancillaries (Including GRP Doors and Supports)

Safe cooling tower access is of utmost importance for the operatives’ safety when carrying out cooling tower inspection and maintenance. The design, manufacture and installation of lightweight GRP access doors to cooling towers ensures safe ease of access to internal components. Spare access doors and door seals are available on short lead-time as required.

GRP Supports for supporting the cooling tower pack and drift eliminators are very durable but have the advantage of being lightweight, so are very easy to install and remove. We can design and advise the appropriate size of supports for your cooling internals as required.

We can provide replacement GRP components for most cooling tower materials of construction such as stainless steel and mild steel, such as troughs and deflectors. Replacing steel components with GRP may offer lightweight, robust, non-corrosive, long-lasting and affordable solutions to recurring issues.

We are also able to supply the following replacement parts normally by return:

- Immersion heaters with built-in thermostats

- Fan control thermostats

- Ball float valve assemblies

- Access door seals and fittings